400 kinds of rice flour produced by our original manufacturing method

〜From Japanese sweets to Western cakes and breads〜

From Japanese confectionery to rice flour shop

In Japan, rice flour has been made from rice and used as an ingredient in Japanese confectionaries since the Nara period (1300 years ago). Today, the technology has improved dramatically, and rice flour is used in a wide range of fields, including not only Japanese confectionaries, but also Western confectionaries, breads, and cuisine. Kojo Seifun Ltd, located in Kagoshima, Kyushu, is a prominent player in the Japanese rice flour industry. The company was founded by the second generation of a family that ran a Japanese confectionery shop in the area, who suggested that a Japanese confectionery shop that could discern the good and bad qualities of flour should start a flour shop. Since then, the company has continued to “make flour with confectionery in mind.

Seasonal Japanese sweets and rice flour

Japan has four seasons, and people enjoy different wagashi in each season, for example, sakura mochi from February to April, kashiwa mochi in early May, and tsukimi dango in September. Rice flour of different types and grain sizes is used to make different types of rice flour: for sakura mochi, for kashiwa mochi, and for dango. This has enabled the expression of unique and delicate tastes and textures.

Overcoming Weaknesses. Evolved rice flour

Kojo Seifun Ltd, manufactures a variety of rice flours for Japanese confectionery, and as it continued to develop its own unique combination of rice flours, it became possible to produce flours that could compensate for the weaknesses of rice flours.

In the past, when rice flour was used, the finished product was inevitably dry and rough. However, with the new rice flour, the result is moist and fluffy.

Such advances have made it possible to incorporate rice flour into recipes in place of wheat flour. Rice flour does not cause the allergic reactions that wheat flour does, and it is low in calories. Rice flour also has many advantages, such as low oil absorption, which allows for crispy frying.

Currently, Kojo Seifun Ltd. manufactures various types of rice flour, including joshinko, joyoko, jomochi flour, karukan flour, daifuku flour, and rice flour for baked goods and breads, etc. The company also manufactures rice flour in small batches of 1 kg or 5 kg. When the flours are included, there are approximately 400 varieties. Although they may seem similar, they are all different and support a wide variety of Japanese and Western confectionery production.

We would like to focus on developing mix flours that make it easier to make confections and breads,” said Katsuya Nose, president of Kojo Seifun Ltd. We will continue to move forward for the sake of the confectionery industry, which has been facing a chronic shortage of labor in recent years.

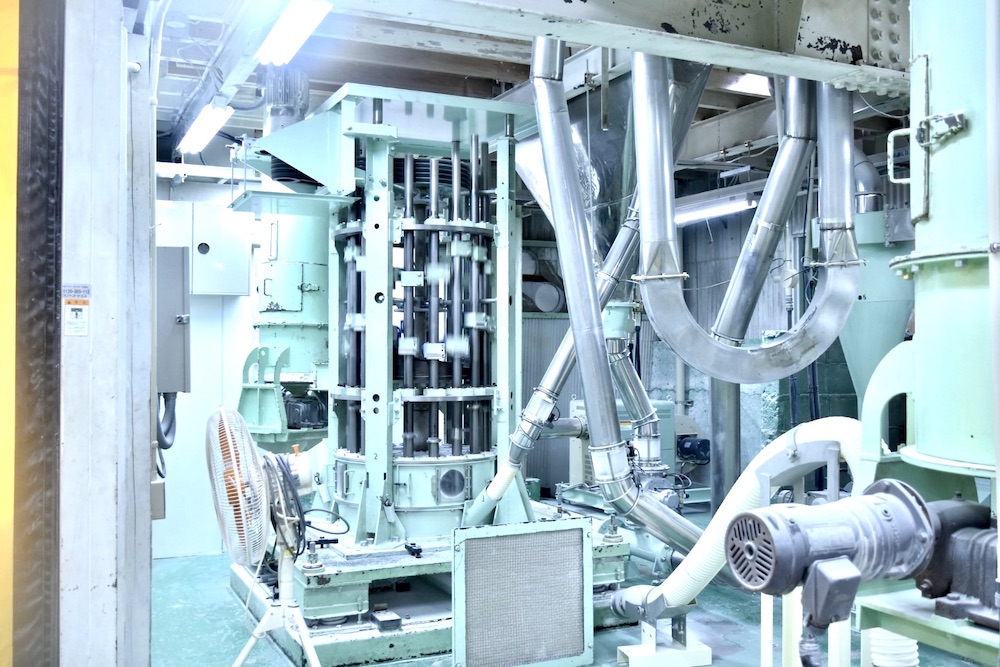

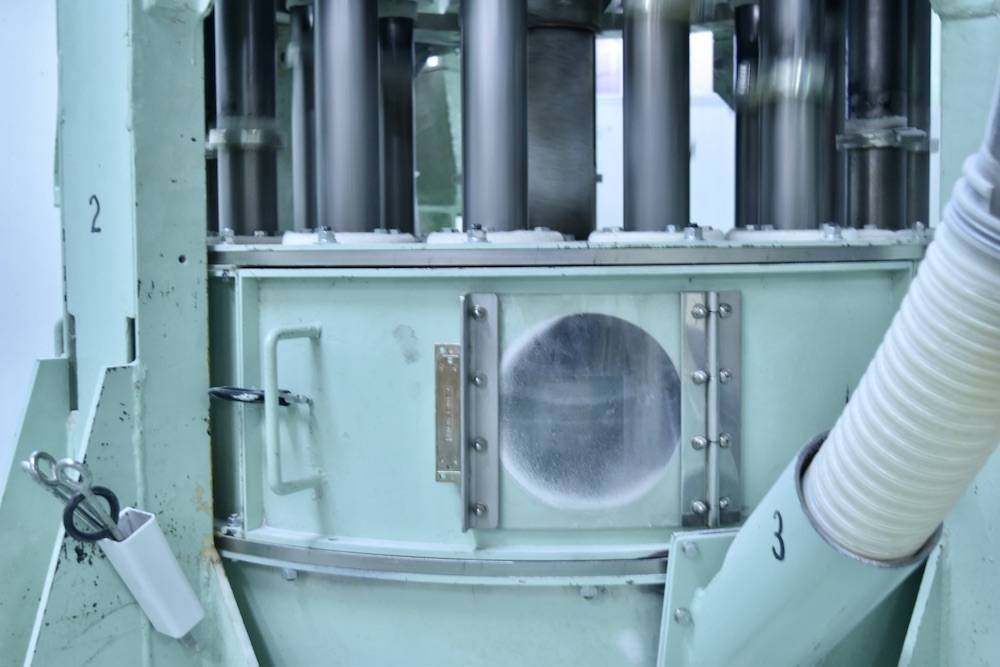

Factory Introduction

①Rice polishing and sorting

The brown rice purchased is milled at the mill in the factory and turned into white rice. The brown rice used includes “Emitawawa” from Kagoshima and “Fukunoko” from Fukuoka. The bran produced when the rice is milled is used as feed for pigs at a pig farm in Kagoshima Prefecture.

After the surface of the polished rice is polished by a machine, the rice is then passed through a machine with built-in infrared rays and cameras to remove foreign substances.

The surface of the polished rice is polished by a machine, and then it is placed in a machine with built-in infrared rays and cameras to remove foreign substances.

②Rice washing and drying

After sorted rice is washed, it is dried in a drying room. Although drying rice at high temperatures with hot air, etc., can shorten the drying time, rice is dried in a near-natural environment with controlled temperature and humidity because exposure to heat above 45 degrees Celsius will cause rice to become pasteurized and lose its flavor.

③Pulverization

The dried rice is then ground into flour in a milling machine. The rice is poked and then advanced to the next stage, where it is ground into a powder.